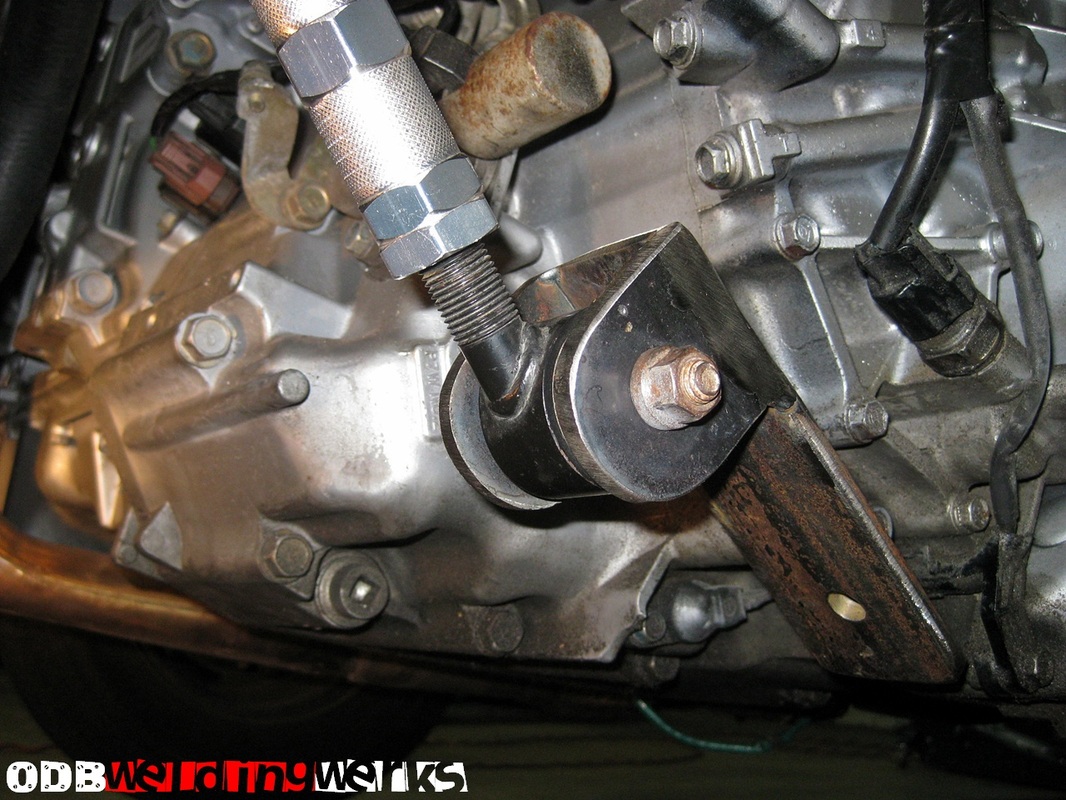

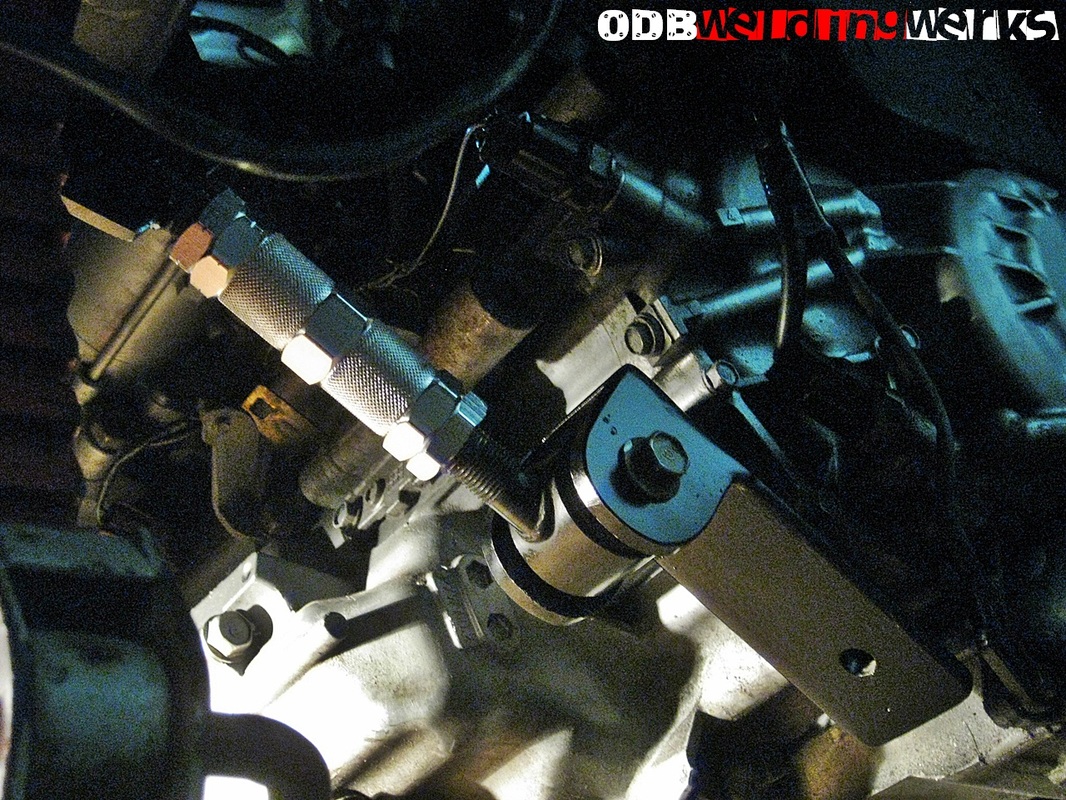

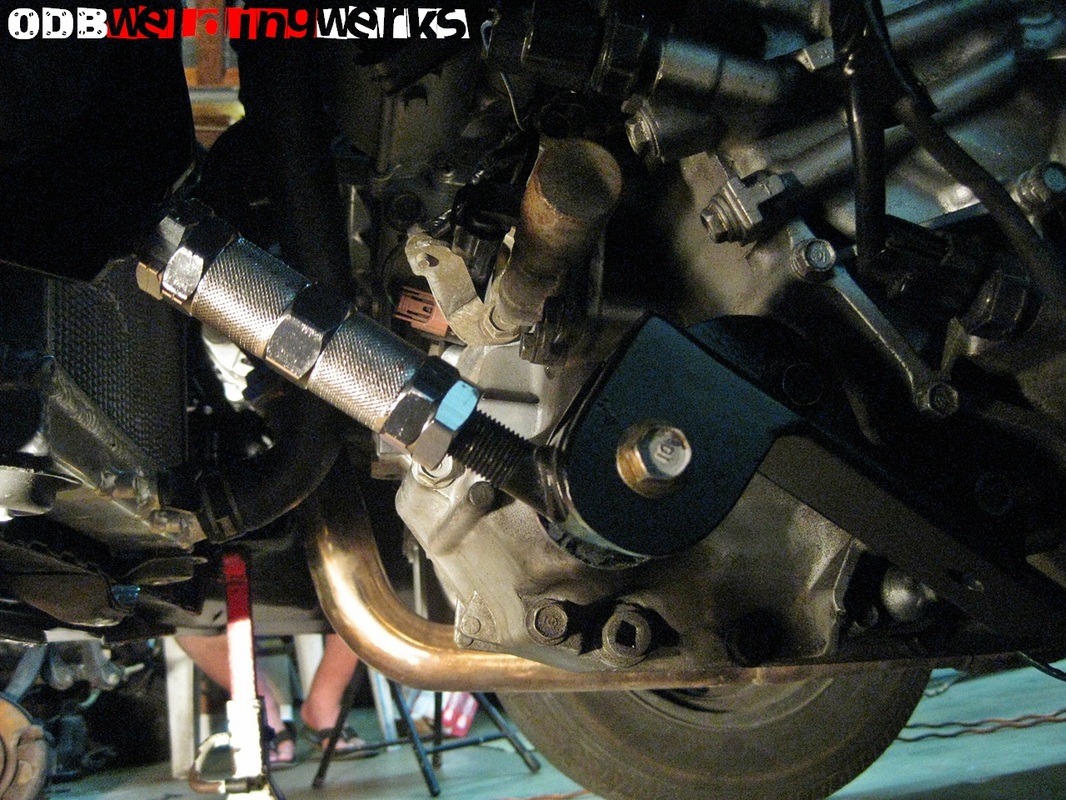

After raising the engine to the higher setting on Austin's Integra we had to modify his upper mount bracket in such a way that I no longer trusted it to support all of the weight of the transmission. Remember this J swap has a triptronic trans. We decided to use a civic rear camber kit to make the connection. Not bad for 1 day and using random parts laying around the shop. Here's what we came up with.

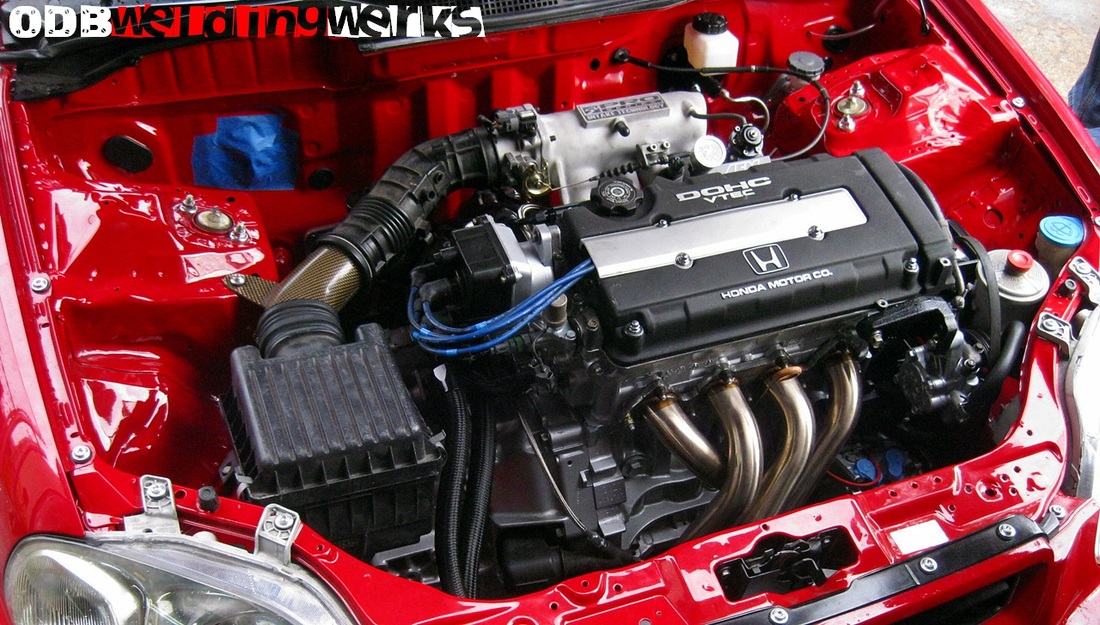

She runs! Now its time for break in and tuning. After a couple weeks of driving shell be back for AC lines.

****Also dont mind the blue tape on the firewall, its holding the caps in place on the evaporator. A quick job on some EG shock towers. Its about done now, just a tad more body work. Pics speak for themselves. Thanks for watching.

Plate work is done. Stay tuned for more updates once it returns from Rogue for paint and finish work. They are going to add a few extra touches as well.

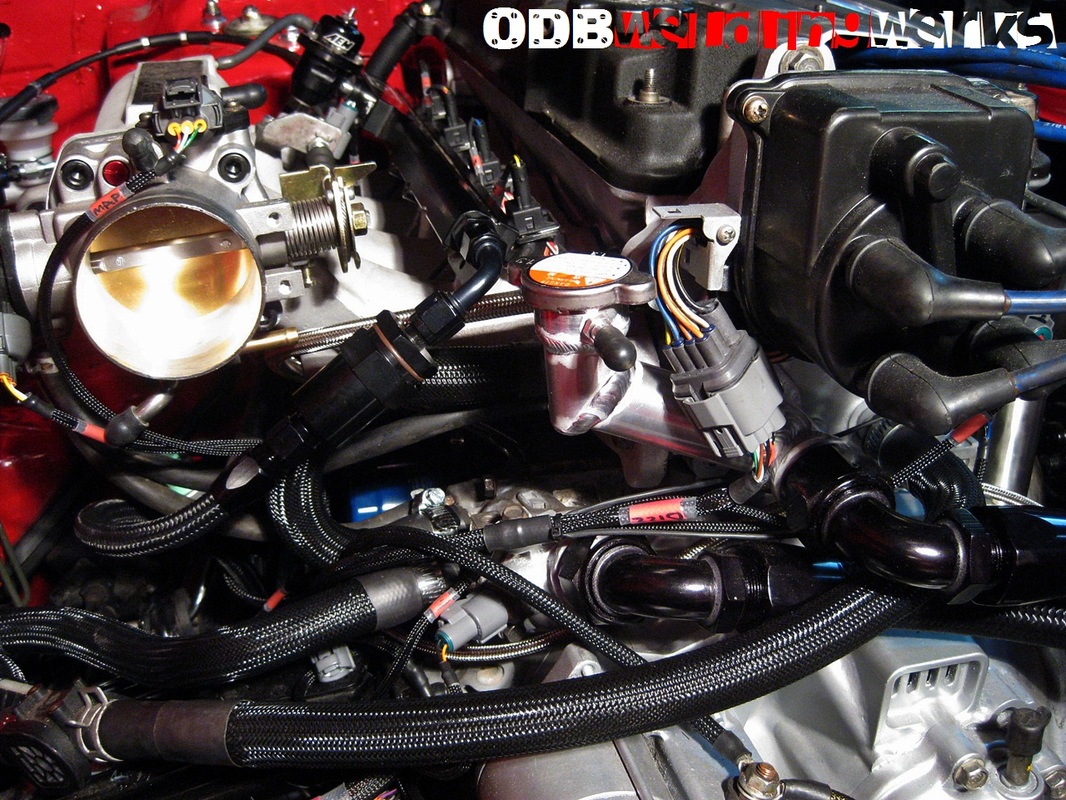

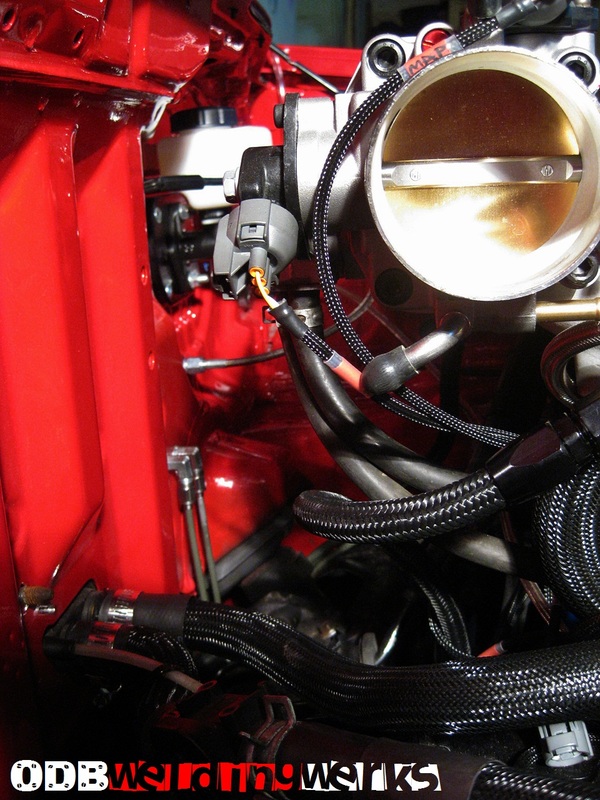

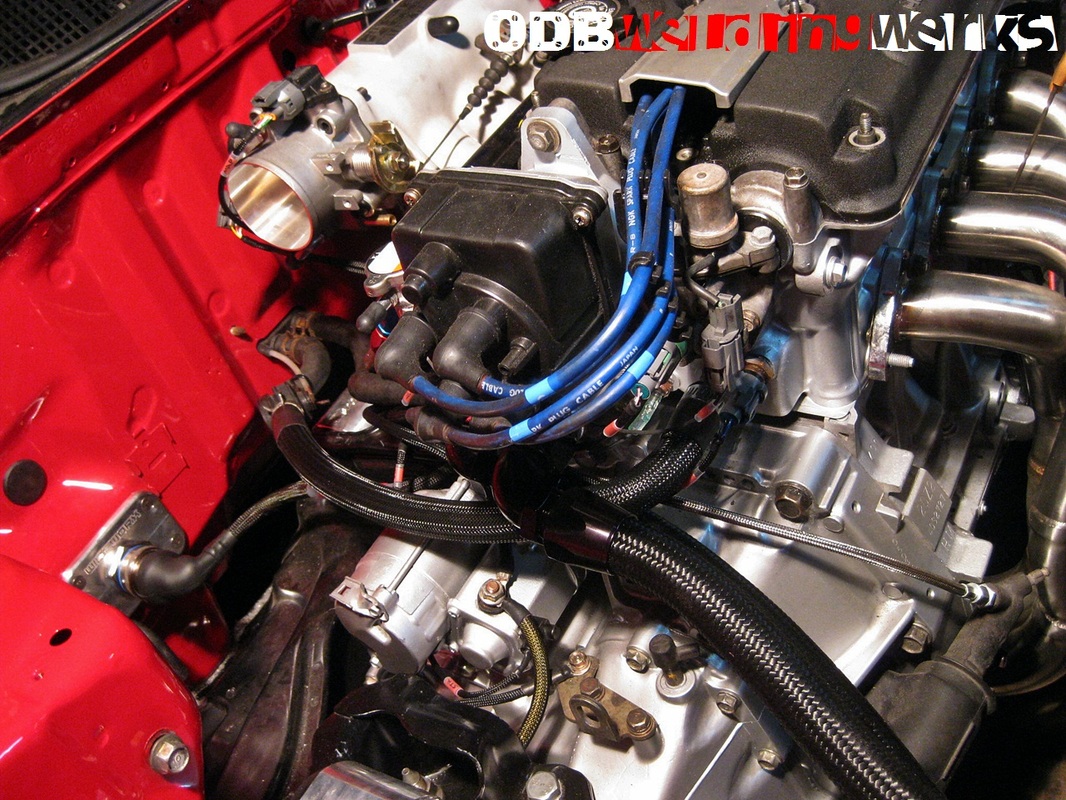

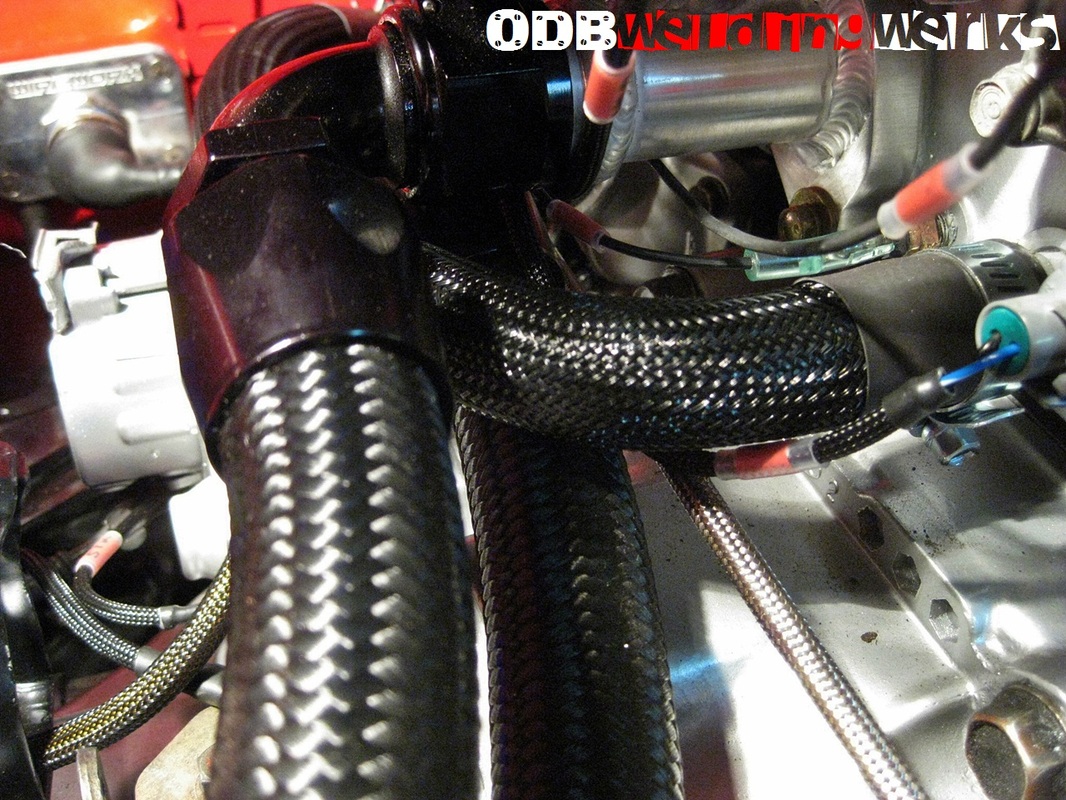

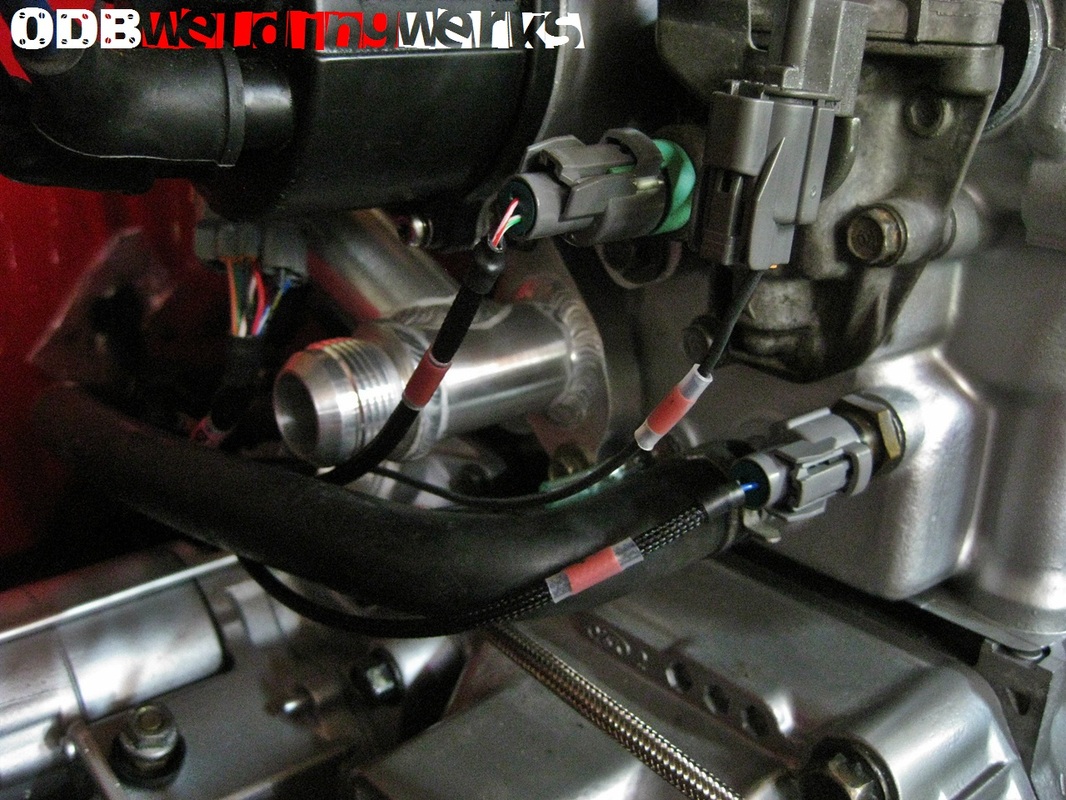

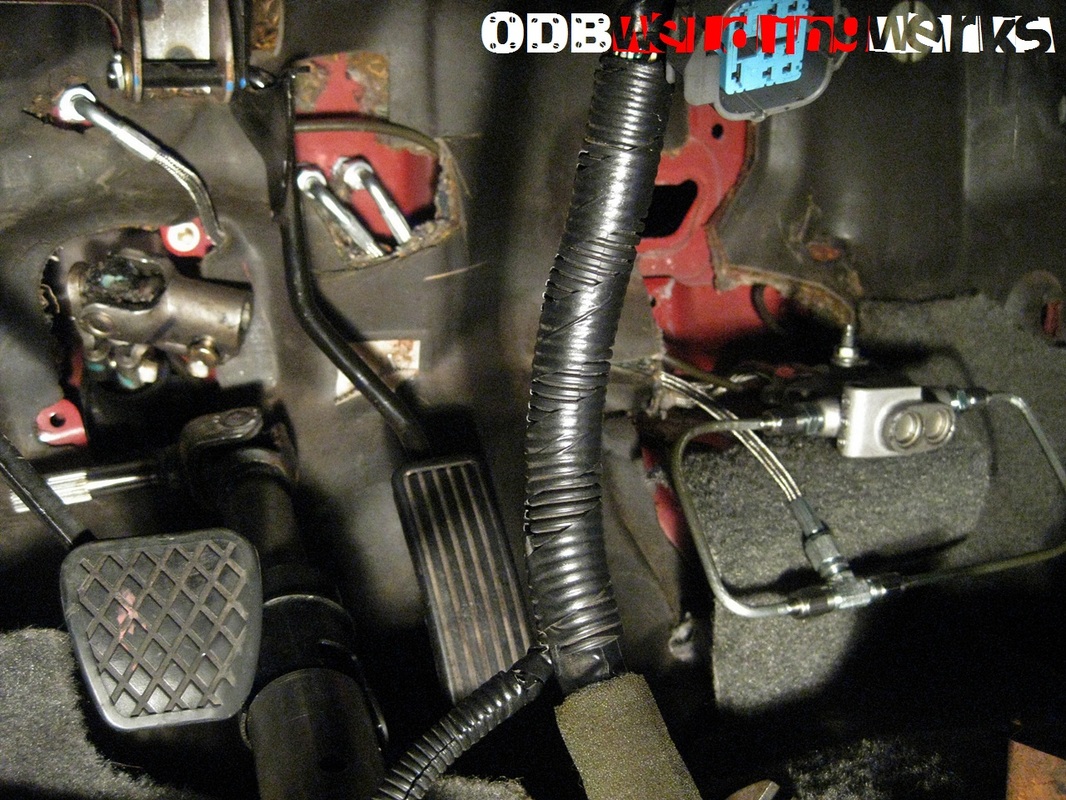

Over the last few days we have been finishing up the EK project. Everything is finished to the last detail, minus the exhuast connection. As soon as the flange arrives it will be time for start up. As soon as Kenny gets the new engine broke in we will take the car to my good friends at Cool Cars Inc and Adam and I will make the ac lines. Heres some pics, thanks for watching. It is a bit busy here but since he kept his heat not much could be done. I also wrapped all the heater hose in nylon sleeve and heat shrinked the ends. Came out pretty good I think.

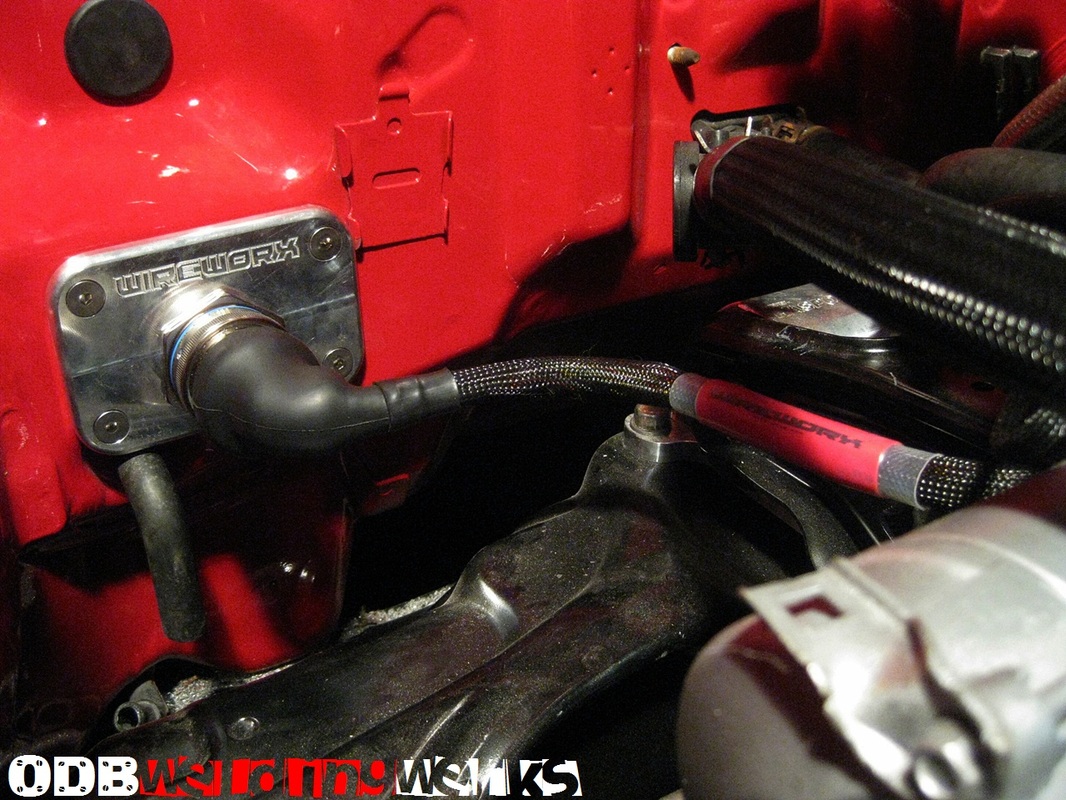

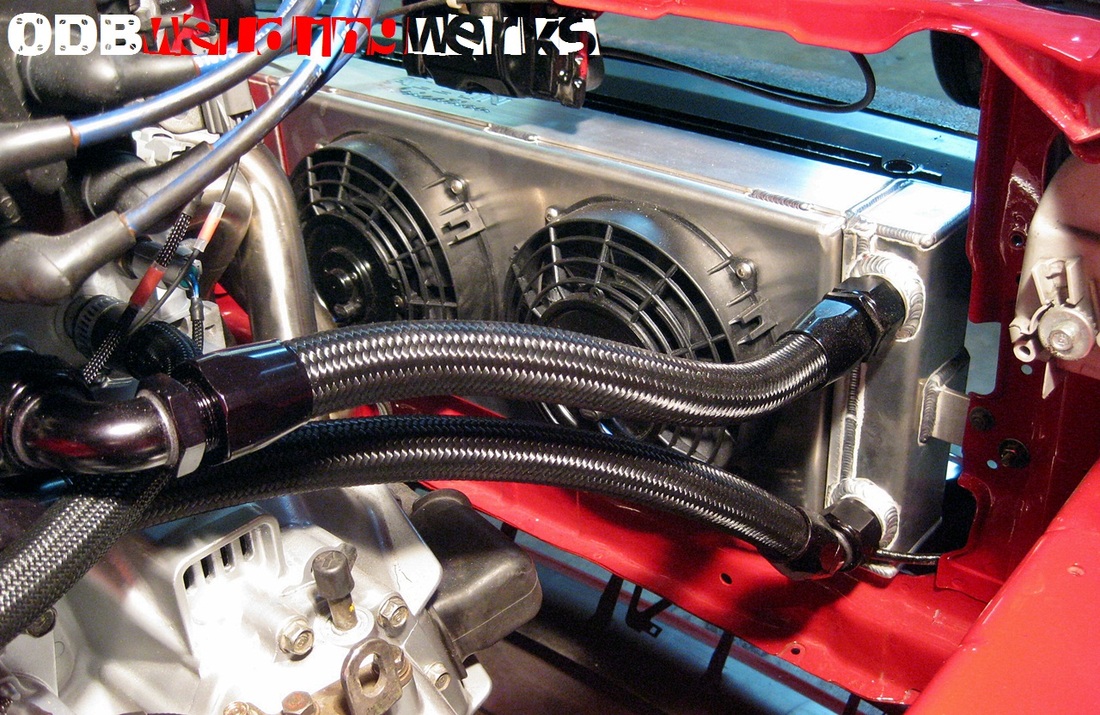

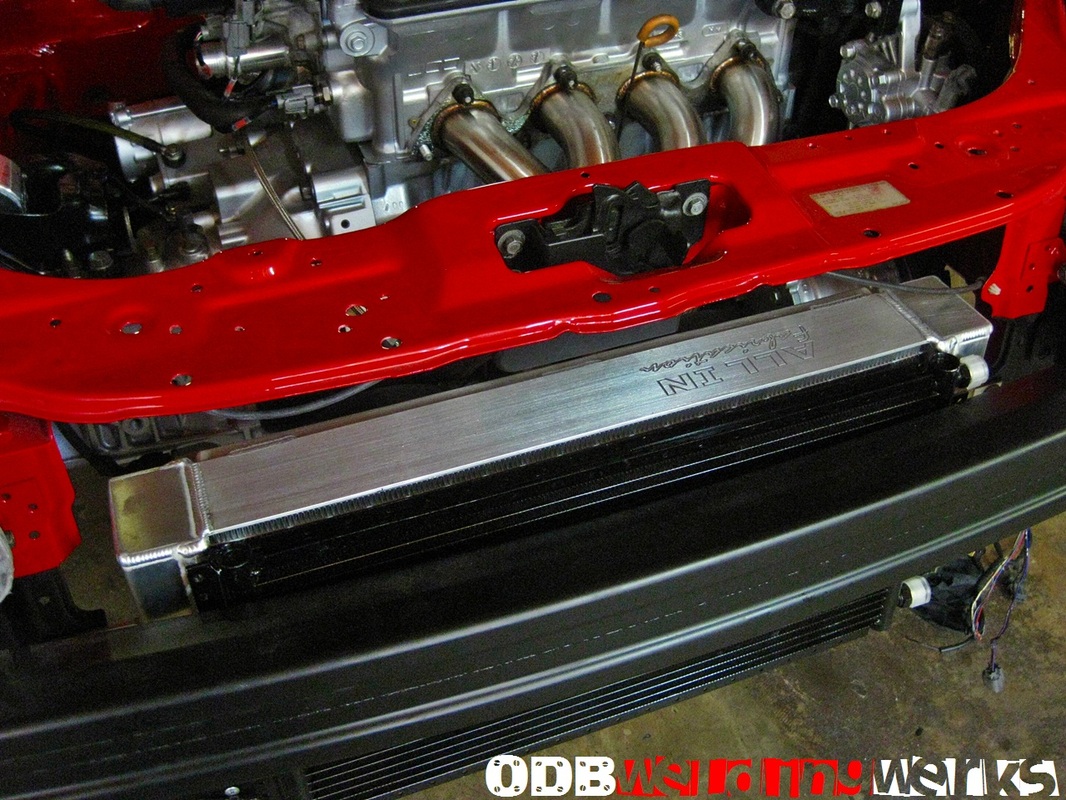

Car is just about done. Expect start up on friday. Here are some pics. This spot worked out really well. Never seen one put here before. Thanks WireWorx. Nylon sleeved and shrinked heater hose. Factory harness entrance block off plate. Decided to integrate a bulkhead terminal for the charge harness. Worked out quite well. Some All in Fab love.

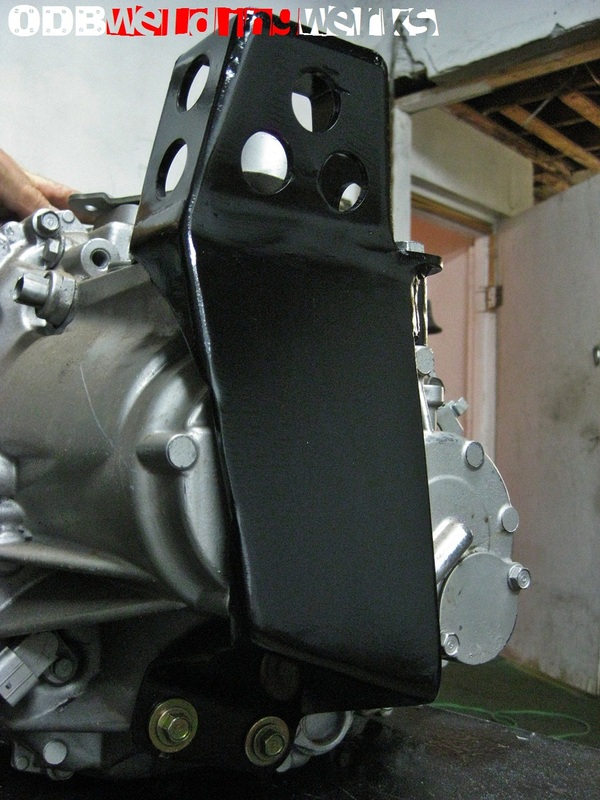

If you have a J swap or have had a j swap then you know about the problem with the hasport trans mount. They sometimes have a tendency to break the trans case. Especially those of you boosting and supercharging. I have a solution for you. I can modify your mount bracket so that it will never break. Its gone through 2 years of daily driving and many passes at the drag strip. Its constructed out of 3/16 A36 steel and wraps around the back side of the case and bolts in place at the bottom. On with the pics. If you are interested in this service contact me at [email protected] As you can see i added the tab with the extra 12mm bolt bolt to add some rigidity to that corner of the trans. Especially since that is right where it likes to crack the case. As you can see this trans case is broken in the typical spot. Exactly what I am trying to prevent.

In the last few days a ton of progress has been made on the Kenny's EK hatch. So far we have installed, Wire-Worx wire harness, the All in Fab tucked radiator condensor combo minus lines, dash, the remaining portions of the brake and wire tuck, reinstalled axles and passenger spindle(neede a bearing), engine acessories, and other misc. Roughly 12-14 hours of work left and assembly will be complete. Then, start up and probobly a half a day in bleeding and burping, lol. Heres some pics, enjoy. You really cant beat the quality and craftsmanship of Derek Chorum's work. The fitment on this is spot on. It was a breeze to install. Everything Xavier makes fits like a glove. Hats off to Wire-Worx for another perfect harness. I know its a little odd looking but it works out perfect for all the heater/ac box clearance. Even reinstalled his firewall blanket since he is keeping all his climate control.

|

RSS Feed

RSS Feed