The last week has been pretty busy. Got the EG bay finished up. Now its cage time for it. The FUNK EK bay is very near completion and the Eclipse wire tuck is complete.

Took a trip over to the Dannspeed garage to see the finished product on a DA I did a little minor shave work on a few months back. I also did the wire tuck and Jason and I did the brake tuck. Paint was done by Steven Brown.

Also shipped out more shock towers in the 2 weeks than Ive sold in total.

Heres a few pics.

Davids EG

The FUNK EK

Joshs Eclipse

The ODB/Dannspeed colab DA. A good representation of a MILD shave.

So far this week Ive been on 2 different cars. Yesterday I worked on Noah's EK (aka the fashion wagon). Got most of the plate work finished and all the repairs needed on the passenger side front panel. As you can see in the pictures I had to remove the outer bay panel to repair it. More updates on this car Thursday night.

Today I work on David Green's EG hatch. Got the mounts targeted, built and installed in 1 day. Also managed to start on the front plates. Pictures of todays process below. More updates later in the week.

Been working on a multitude of cars this week. David's EG, My personal DB7, Noah's EK and Josh's Eclipse.

First up is David's EG. Didnt get to spend as much time on this as I would like but never the less still managed to get quite a bit done. 99% of the holes are welded and Ive already begun make the temporary brackets for his new engine mounts. Not as many pics as I would like but heres a few.

Next up is Noah's EK. We will be doing the bay, shock tower extensions, some panel repair, new front core support and all of the tuck and plumbing work. So far the bay is 90% welded, the extensions are installed and the panel repair is almost complete. Also once Im done with the metal work it will be in the hands of the pros at Rogue Auto Werks. More updates on this one next week.

Oh neat, one of my personal cars and Im actually working on it, lol. Plans are to pull the engine, shave the bay, do a better tuck job and get her to paint. More updates on this one soon as well.

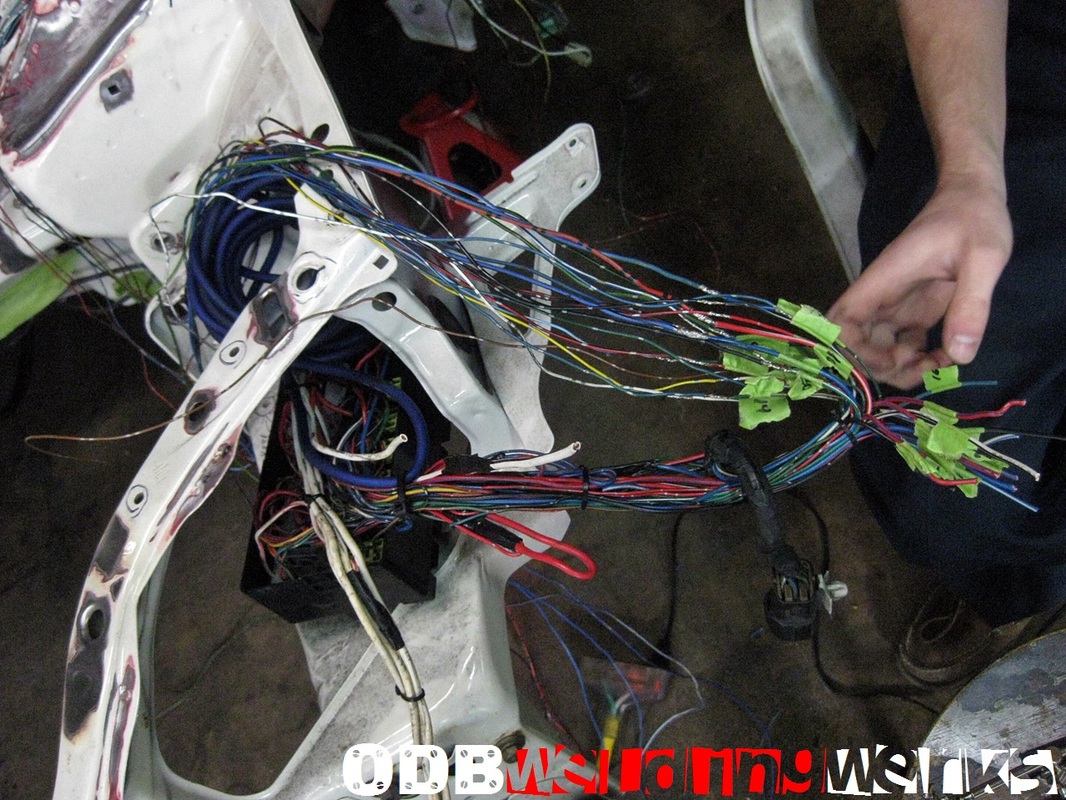

Last up, Josh's Eclipse. This week Josh and I have been working to get his wire tuck complete. Hopefully by the middle of next week the wire and brake tuck will be done. Using some of my "Honda" tricks with this one.

Today was a busy day. Finished the diss assembly on David's EG and also got a really good start on the bay prep. Heres a few pics.

Over the last 3 weeks things have been very busy with the shop and everyday life. As you can imagine the Holidays make things hectic.

Since my last post the RSX was completed but I dont have any finished product pics yet. I have some as soon I a able. The CRZ is wired and ready for basemap and immobilizer procedures. Once I have that I can make sure everything is working properly then we can start her up.

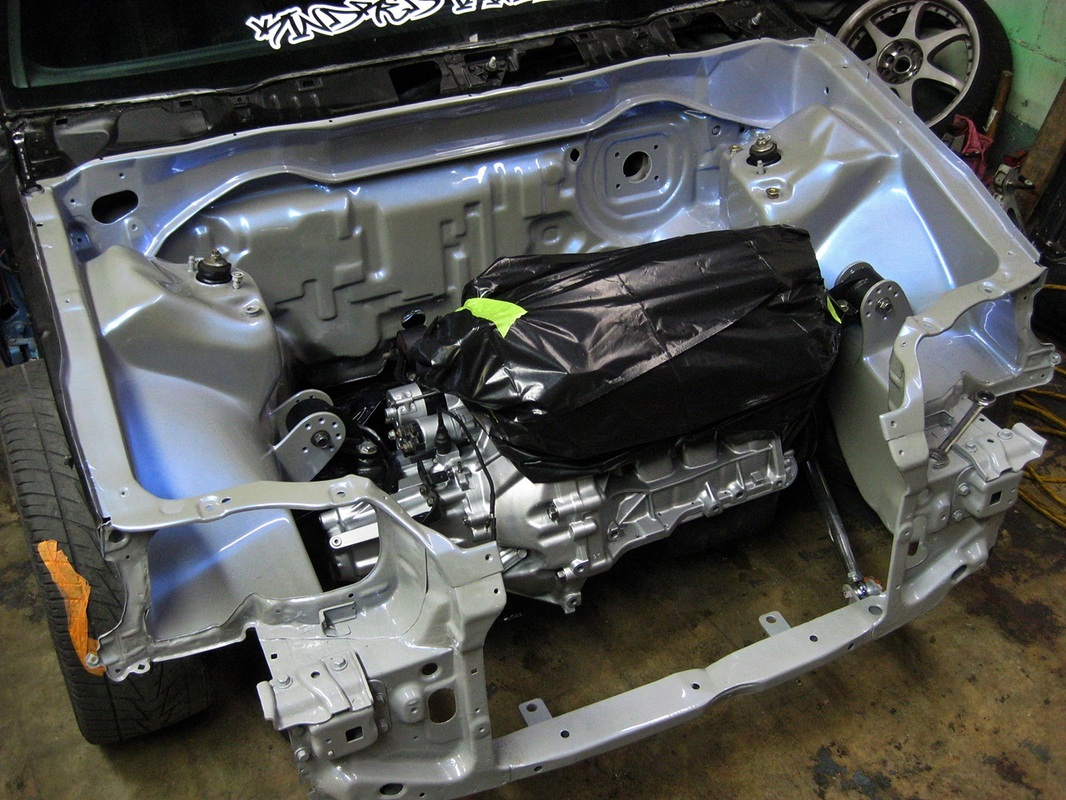

Also got a new project in. A very clean and well done EG hatchback from David Green in South Florida. He is a shop owner himself and has done a great job on the civic so far. Car is getting a fully shaved bay, 4pt cage, rear seat delete and much more. Today we started diss assembly. Expect more updates on this car and several others soon. Thanks again for watching.

Shes just about wrapped up. We went a little further than originally planned so Ill be back there for a few more ins and outs. Heres a couple pics from today.

Started out the week with some metal work in Troy's RSX bay. In the am tomorrow I will be finishing up the metal work in the bay. After Im done its up to Christian @ Autotechnics to get her wrapped up for HIN this sun. Heres a few pics of some of today's work. More updates tomorrow.

So far this week its been nothing but wiring. Most has been spent on the CRZ getting the min harness in order the rest has been a gauge install on Brians carbon monster.

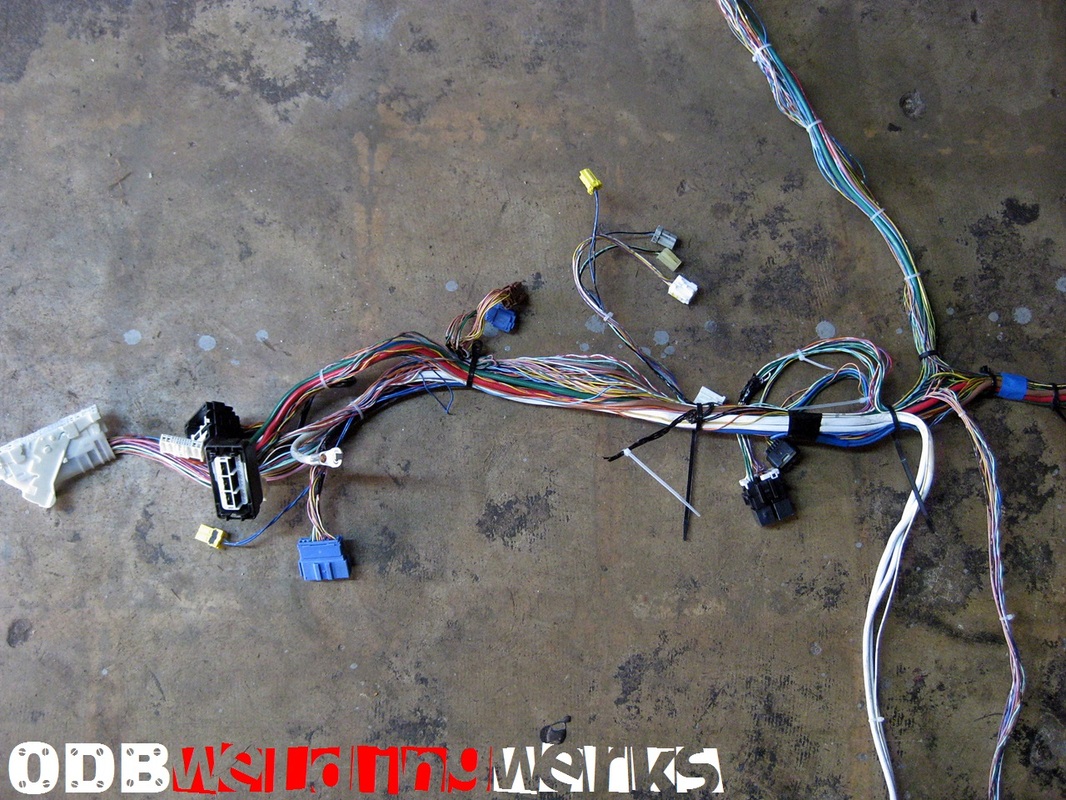

The main harness on a CRZ is an odd one. The ECU lives in the engine bay on this chassis so in turn half of the main harness is inside and the other is in the engine bay. The driver side headlight harness is also integrated in to the engine bay side of the main harness. This makes doing any sort of wire tuck a difficult task but still doable. As you can imagine this took quite a bit of cutting and splicing to make happen.

In our case we used a Wireworx engine harness with quick disconnect so this made the tuck process much easier but the main harness still needed extensive work to be able to accomplish a proper wire tuck. In using the WW harness it put the B and C ecu plugs inside along with the main harness interface plug. But the ecu A plug was still on the main harness in the bay a long with the C126 tower plug needed to be wired to the WW interface plug. So both of these plugs had to be moved all the way back through the harness to the firewall side. And while I was at it I moved all the AC plugs, SRS plugs and anything else we didnt need.

The result the engine bay side of the main harness is now thinner and has only the needed plugs for the new setup. And everything on the interior side is now where it needs to be to mount the ecu inside and do the proper interface into the WW harness.

Also installed the Innovative gauges on Brians carbon monster. Now.....time for pics.

Everything south of the blue tape represents the engine bay side of the main harness. Everything north represents interior side.

A closeup of the engine bay portion.

The white cables provide power to the electric PS setup, the interior fuse box and it used to provide power to the starter. Now it will Be inside and the former starter terminal will now provide power to the alternator. The stater now gets its power strait from the battery that is located in the trunk.

The rolled up bundle of wires are the ac wires we are no longer using. I didnt want to delete them permanently in case he wanted to get ac back so I just moved them to the interior.

This portion was the original interior portion. Consist of dash interface, fuse box,/PS/pedal switch plugs, relays etc.

This is the ecu plug and the c126 I will be cutting off and re pinning for a different plug.

The backside of the Wireworx engine harness. A long with a male connector and pins for the main harness interface plug I have to wire. A long with the B and C ecu plugs.

Brian's gauges.

Gary's wagon is back in the shop ready for assembly. Very pleased with the way this one came out. There wont be another like it thats for sure. Heres a few pics of the process so far. Hopefully shes running by the weekend.

Today was a good day. I actually was able to take a Saturday off and take the drive for Simply Clean in Daytona. Ive been to another SC meet in the past and it wasn't even close to as organized or well planned out. Everything was very smooth and easy and the staff did a great job this go around. Even the police didn't seem to be a hassle. I also got to put a few names to some faces and hang with some friends as well. Overall I think the meet was a great success. Thanks Simply Clean.

Thank you to all of my customers and supporters out there today. I greatly appreciate you all. Heres a few pics, not many but a few. Thanks for watching.

Also big thanks to Daniel Kelly for giving me a lift.

Kenny's super clean EK hatch

Anthony's beautiful EG hatch

Noah's fresh EK, strait out of the paint booth at Rogue Auto Werks

Elby's K swapped 4 dr EK

Clayton,s nicely done Dodge Calibur

Austins's DC2

Not sure who owns the clean EG hatch now but I know the person that built it.

Maybe when Im old and the kids are gone. . . . . . lol. Wait . . . . . . Im already old, shit!

RSS Feed

RSS Feed